Formula 1-technology for hydropower

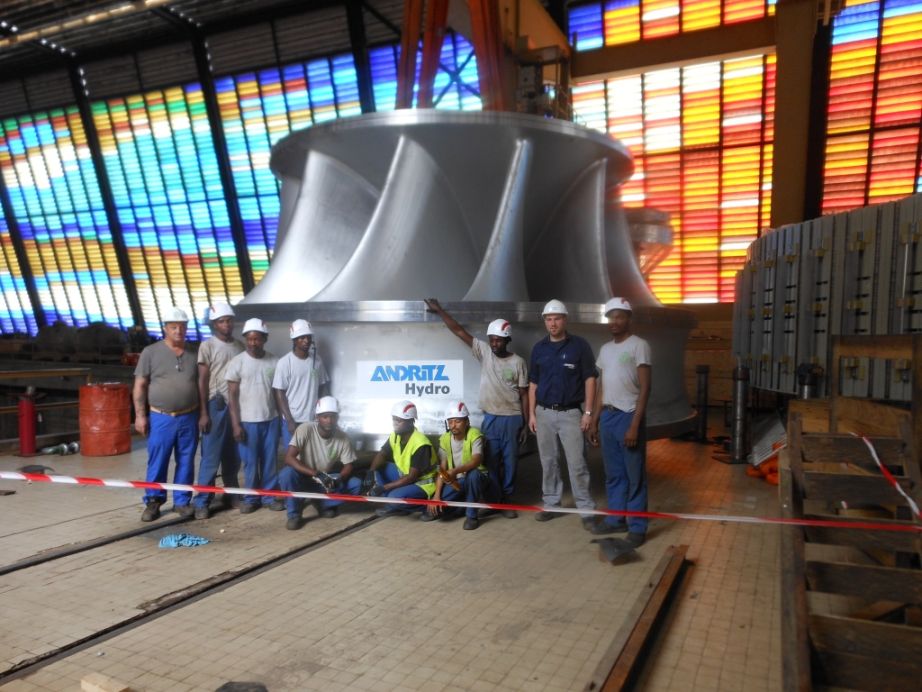

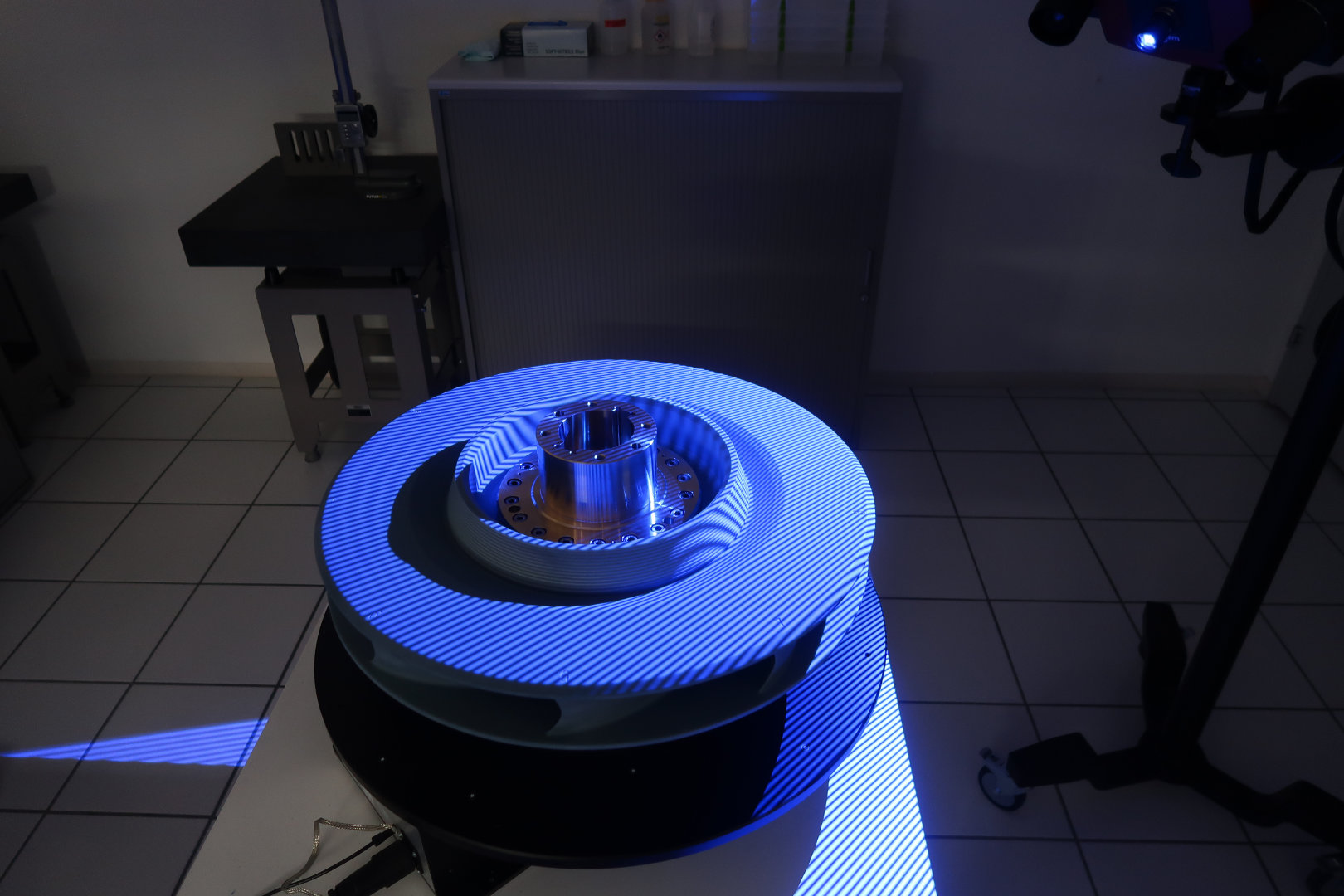

The development of modern hydropower plants is one of the major challenges facing the industry. Manufacturers are constantly optimizing their turbines and designing them exactly according to customer requirements and external conditions such as water pressure and the field of application. In addition to complex CFD calculations, model tests are also used. In these tests, a power plant is replicated and is tested and verified in water using true-to-scale turbines with diameters of up to 580 mm. In addition to high-precision manufacturing, fast delivery times are also important.

In the past, our customer manufactured its turbines using conventional methods such as milling or casting. As the geometries are becoming more and more complicated due to the increased efficiency, the customer has reached the physical limits of these methods. We know no limits and have taken on this project.

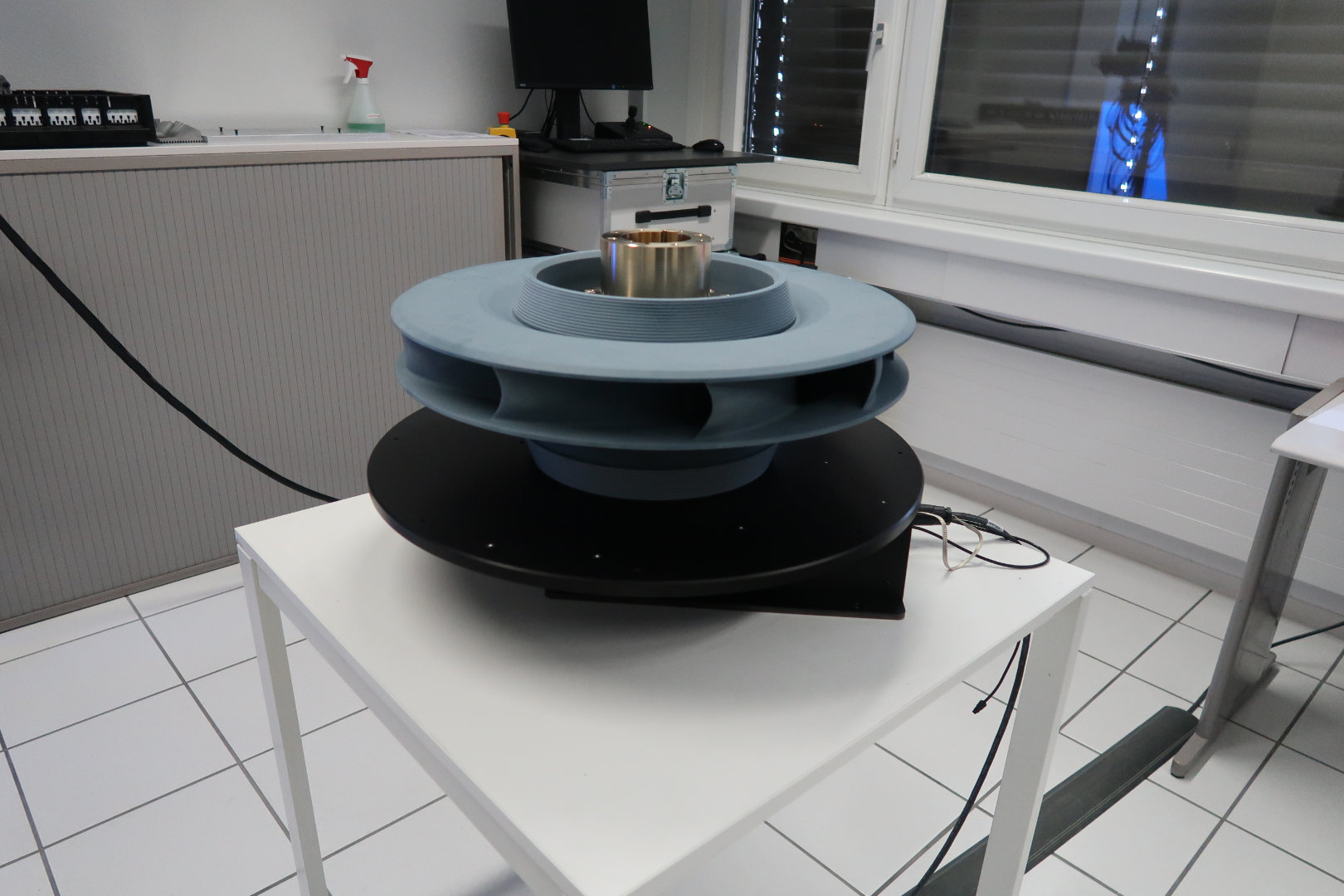

Together with our customer, we have adapted the model building process and optimized it for additive manufacturing using plastic 3D printing. We opted for the SLA material Accura® Bluestone due to its low water expansion. Our solution makes it possible to manufacture and test very complex geometries. The delivery time was reduced by around 25% and costs by around 15%. This solution allows hydropower plant operators to verify the efficiency of their plants at an earlier stage than they could before.

Today, we manufacture around ten different turbines per year with diameters ranging from 350 mm to 550 mm at a consistently high quality and support our customers to ensure that the testing process runs smoothly.