Because complexity won’t stop us in our tracks

From motorsports and air and space travel through to your specific industry: if time saving is important, lightweight constructions with complex structures and geometries are used, and components need to be simplified whilst also being subjected to extreme mechanical or thermal stresses, 3D metal printing is the first choice.

We make use of state-of-the-art technologies to provide you with endless possibilities. We are your ideal partner for everything from design and printing through to post-processing and validation

We’ll support you from the initial idea and prototype phase right through to industrialisation, and are the perfect partner for additive manufacturing. With our knowledge and expertise, we also provide support in critical phases and contribute to your success.

Benefits of 3D metal printing at Sauber Technologies

Low costs

Lightweight

Maximum stability

Customised implementation

Unique industrial manufacturing

We’re proud to operate Switzerland’s largest and most state-of-the-art additive manufacturing facility and provide you with the same outstanding technologies and service as those used in Formula 1. To ensure that we can offer you the best solution for your project, our development laboratory, all steps of reworking and our quality assurance have been designed purely with additive manufacturing in mind. Our production is also AM-certified according to ISO 9001.

Parameter development

Together with our partners and suppliers, we are constantly taking additive manufacturing to a whole new level and pushing boundaries in the process. We develop tailor-made production parameters with customised layer thicknesses or laser parameters, which have a significant influence on construction time, quality and costs.

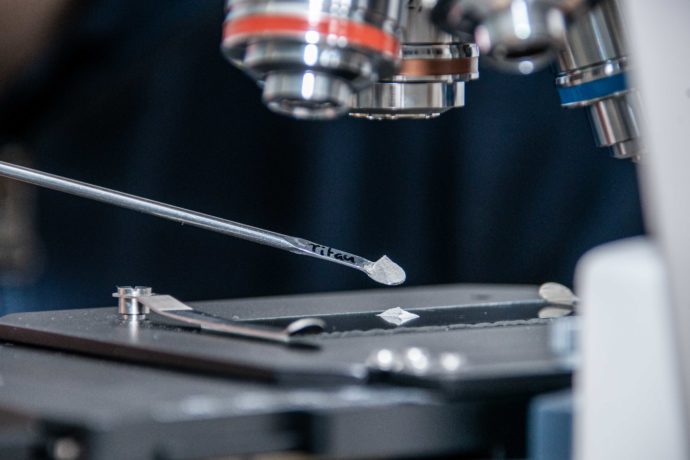

We use state-of-the-art technologies to gain an understanding of how a component behaves in its field of application.

Everything is possible, from fast prototype parameters through to parameters for high loads. Our ultimate goal is to always offer the perfect solution for a specific application. Intensive cooperation with our customers is just as important as having an understanding of materials and processes.

Quality & processes

When manufacturing components, we leave nothing to chance. From the raw material through to the finished component, we monitor the entire process and are thus able to detect irregularities before they occur. The high level of safety and clear processes enable us to manufacture the best products – with unlimited reproducibility and premium quality. This has enabled us to turn additive manufacturing into a method that can be used on an industrial scale. Topics such as “production on demand” and the “digital supply chain” become tangible and applicable and are no longer a mere vision for the future.

Our AM materials

- Aluminium – AlSi10Mg

- Titanium – Ti64

- Scalmalloy® – AlMgSc

- Further materials available on request

You can find further important information about our AM materials here.

Download material listPost-processing in-house

In order to benefit fully from metallic 3D printing, it is important to be familiar with all aspects of it. We aspire not only to know them, but also to implement all relevant processes and steps in-house.

- Automated support removal

- Sandblasting

- Wire and sink erosion

- 5-axis CNC machining

- CNC turning

- Surface finishing (vibratory grinding, polishing)

- Quality assurance

- Test setups

Ultramodern machinery

Win-win partnership

Rösler AM Solutions

We are proud to work closely with the best partner for the surface treatment of additively manufactured components. Rösler AM Solutions supports us not only with the best equipment, but also supports us and our customers with tailor-made solutions for the best products.

ADDITIVE INDUSTRIES

Our metal 3D printing partner has been Additive Industries right from the very beginning. These facilities enable us to realise the most challenging projects. With Additive Industries, we can always be safe in the knowledge that we are securing the very best solutions and outstanding products for you.

Additive success begins with engineering

We will share our expertise and many years of experience with you in order to support you with challenging projects right from the word go.

Formula 1-technology

for legends

There are only two original Ferrari 340 America Barchetta in the world. In one of these legendary vehicles, the rear axle transmission broke. We had the pleasure of manufacturing the necessary spare part for our customer using metal 3D printing in AlSi10Mg and our internal mechanical production system, allowing the legend to take to the road and the racetrack once again.

To the story

Got questions?

Leonardo MahlerDo you have any questions? Simply get in touch with me and I will be happy to advise you.