Harness the development techniques honed at the pinnacle of Motorsport for your project

As visionaries, we are your innovative and experienced partner for state-of-the-art aerodynamic solutions – from motorsports, automotive engineering and aerospace through to different industrial applications and customer-specific issues.

Customers & projects, challenges & commitment

Our customers come from all manner of industries. Leading vehicle manufacturers, motorsport teams and well-known companies from a variety of industrial sectors use our infrastructure and expertise, especially in the prototyping and development of previous versions for new products and models.

Turnkey Formula 1development solutions for your needs

As a leading provider of aerodynamic services, it is our mission to achieve your goals and to actively support you in your development. In doing so, we shrink from almost no challenge. We specialize in the complex development process of automobiles, trucks, rail vehicles, buildings, sports articles or industrial plants up to aerospace objects. From planning, conceptual work, simulation and physical testing you can rely on us to help you realise your needs, great or small.

Within Motorsport we specialize in developing LMH, LMDh, GT3 and all open wheel race cars, from localised support to full aero development programs.

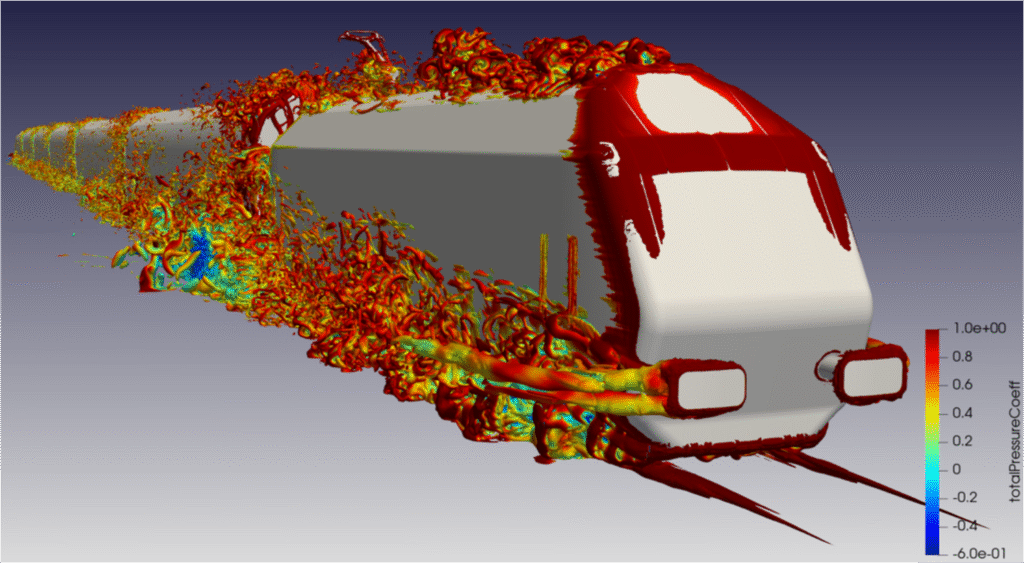

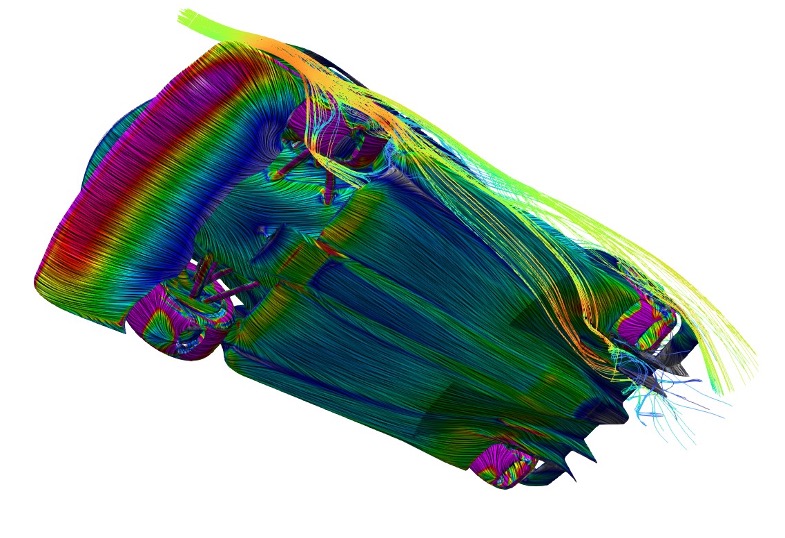

Computational fluid dynamics (CFD)

CFD is the solution for developing aerodynamic solutions quickly and efficiently. We operate on our own supercomputer in Hinwil Switzerland, the very same used by the Formula 1 team which allows us to perform numerous calculations in rapid time. We offer a full development package, from consultation, CAD surfacing, CFD model building and development loops. Through using the same methedology used by our Formula 1 team, our accuracy and correlation to real world conditions is state of the art.

With years of experience in the motorsport industry, Sauber Technologies has accumulated a wealth of knowledge in aerodynamics and fluid mechanics. Our close association with Formula 1 has allowed us to develop groundbreaking technologies and methodologies that transcend the racetrack, finding applications in diverse industries.

Sauber Technologies CFD Software and Computing Cluster

To meet the unique demands of our clients, we have developed our own state-of-the-art CFD software. This proprietary tool, refined through years of Formula 1 experience, enables us to provide tailored and comprehensive solutions for industrial fluid dynamics challenges.

In addition, our advanced computing cluster empowers us to handle complex simulations and large-scale data pro-cessing efficiently This ensures rapid turnaround times, allowing you to make informed decisions quickly and optimize your processes without unnecessary delays.

Partner with Sauber Technologies for CFD Excellence

When it comes to computational fluid dynamics and the benefits of Formula 1 technology, Sauber Technologies stands at the forefront. Our expertise, derived from years of involvement in motorsport, combined with our proprietary CFD software and power-ful computing cluster, sets us apart as the ideal partner for optimizing fluid dynamics in your industrial applications.

Contact us today to discuss how our CFD solutions can elevate your operations to new heights. Together, let’s drive innovation and efficiency in your industry with the power of Formula 1 technology.

Wind Tunnel Test Model design and manufacture

Your project requires a scale model test program? Rely on us to design, manufacture a model to F1 standards and execute wind tunnel tests for you in the wind tunnel of your choice

Whatever your needs, we will plan and execute tests to F1 efficiency levels.

Unparalleled Precision

Formula 1 demands precision and perfection. We apply the same meticulous approach to your industrial challenges, ensuring optimal fluid dynamics for in-creased efficiency and improved outcomes.

Enhanced Performance

Formula 1 technology is synonymous with speed and performance. Our CFD solutions, driven by Formula 1 insights, enable you to unlock your system’s full potential, achieving superior performance levels and surpassing competitors.

Cost-Effective Solutions:

Formula 1 teams operate within strict budgets, necessitating cost-effective solutions We bring this ethos to your projects, delivering cost-efficient CFD analyses and optimization strategies tailored to your specific requirements.

Benefits of Aerodynamic Consulting by F1 Experts

By choosing our aerodynamic consulting services, you gain access to a multitude of benefits that can elevate your project to new heights:

Unmatched Expertise

Our team of F1 experts brings a wealth of knowledge and expertise in aerodynamic design, optimization, and testing. Benefit from our deep understanding of aerodynamic principles, honed through years of pushing the limits in the fastest motorsport on the planet.

Cutting-Edge Technology

Formula 1 is synonymous with innovation and cutting-edge technology. We leverage the latest advancements in aerodynamic simulation tools and computational fluid dynamics (CFD) to provide accurate and comprehensive analyses tailored to your project’s unique requirements.

Cost-Efficient Solutions

Our aerodynamic consulting services are designed to deliver cost-efficient solutions without compromising quality. By leveraging our F1-inspired methodologies, we provide targeted recommendations that prioritize performance gains while keeping your project’s budget in mind.

Competitive Edge

Gain a competitive edge by tapping into the aerodynamic expertise that drives success in Formula 1. Stand out in your industry with optimized aerodynamics that lead to improved product performance, increased customer satisfaction, and a stronger market position.

Formula 1-technology

for wheelchair athletes

We were commissioned to develop the world’s fastest wheelchair for the Olympics in Tokyo. We used state-of-the-art CFD simulations, wind tunnel tests, 3D printing in plastic and metal as well as the latest knowledge in carbon production to build the OT FOXX M1 with which Marcel Hug won four Olympic gold medals.

To the story

Find out more about how our services can be used.

Formula 1-technology

for potato harvest

Grimme’s Airsep system is one of the biggest innovations in potato harvesting technology. It separates the potatoes from the straw and stones while still on the harvester. Grimme contacted us with the challenge of optimizing the Airsep system.

Using CFD simulations and analyses, we significantly improved the Airsep system by making it lighter and more energy efficient.

Got questions?

James EddisonDo you have any questions? Simply get in touch with me and I will be happy to advise you.