Leading edge for every sector

We combine world-class Swiss engineering, high-end aerodynamics and state-of-the-art production. Our Formula 1 mindset inspires us to strive for excellence to achieve the very best for our customers. Whether you want to develop something unprecedented or need a partner to manufacture high-quality parts, we share your vision. Whether you’re a start-up or an established player, we create world-class solutions and products – for every sector. Including yours. We accompany you along the entire journey, from the initial idea to the development of the finished product and series production.

Our expert knowledge, experience from cutting-edge technology and well-coordinated team allow us to achieve peak performance. You too can benefit from Formula 1 expertise for your project.

Engineering

Where others give up, we feel right at home. Our innovative methods, more than 50 years of experience at the cutting edge of technology and unbridled determination to always be better make us the perfect partner for your technical challenges and the manufacture of never-before-seen top-quality components. Our engineers strive to find the optimum solution for every challenge and draw on the agility and efficiency of Formula 1 developments to stay one step ahead at all times.

3D printing

Only the very best is good enough for us. We combine the complete production expertise of Formula 1 with the largest and most modern additive manufacturing facility in Switzerland. Whether you’re working with plastic or metal, a complex prototype or a product in series production, we make your project a success – from design and manufacturing to the entire spectrum of post-processing, including complex, sophisticated heat treatment. Our products meet the most stringent demands and standards throughout this process.

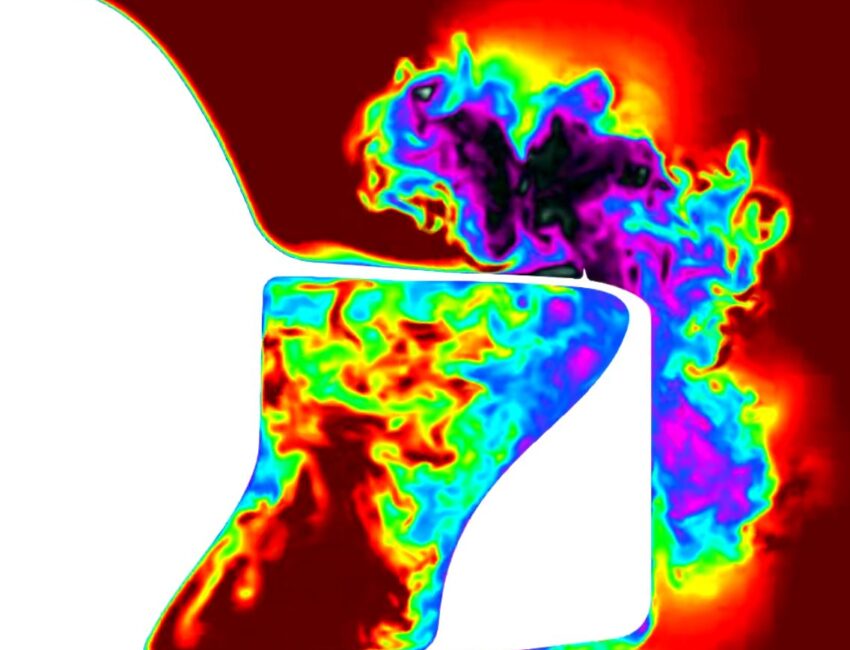

Aerodynamics

Our goal is to achieve victory more quickly and efficiently. Our experts know exactly what it takes to get the best results and develop state-of-the-art aerodynamic solutions. We are proud to have our very own high-tech wind tunnel and the largest CFD cluster in Switzerland.

Formula 1-technology

for hydropower

The development of modern hydropower plants poses major challenges for industry. In addition to complex CFD calculations, model tests are also used. Together with our customer, we have perfectly adapted the model building process and optimised it for additive manufacturing using plastic 3D printing.

To the story

Formula 1-technology

for legends

There are only two original Ferrari 340 America Barchetta in the world. In one of these legendary vehicles, the rear axle transmission broke. We had the pleasure of manufacturing the necessary spare part for our customer using metal 3D printing in AlSi10Mg and our internal mechanical production system, allowing the legend to take to the road and the racetrack once again.

To the story

Formula 1-technology

for wheelchair athletes

We were commissioned to develop the world’s fastest wheelchair for the Olympics in Tokyo. We used state-of-the-art CFD simulations, wind tunnel tests, 3D printing in plastic and metal as well as the latest knowledge in carbon production to build the OT FOXX M1 with which Marcel Hug won four Olympic gold medals.

To the story

Got questions?

Leonardo MahlerDo you have any questions? Simply get in touch with me and I will be happy to advise you.